According to the adhesion mechanism, the viscosity of thermoplastic elastomers TPE and TPR can be divided into two categories: one is self-adhesive, and the other is co-adhesive. Viscosity is an important property of thermoplastic elastomers TPE and TPR. However, in most cases, conventional TPE and TPR do not have functional viscosity, but need to adjust the mixing system to obtain the required adhesion.

The self-adhesiveness of TPE and TPR materials can be understood as: by adjusting the mixing system of TPE and TPR, generally by adding adhesion promoters, the particles themselves have strong adhesion on the surface or after processing into products. Strong adhesion, that is, a viscosity characteristic of TPE and TPR material itself, which is a functional characteristic during its use, so the viscosity of TPE and TPR is called self-adhesive. TPE and TPR self-adhesive materials are mainly soft and hard (usually less than 30A).

The adhesion of TPE and TPR to another material under certain conditions is a manifestation of the co-adhesion of TPE and TPR. In the natural state of TPE and TPR at room temperature, TPR material does not have its adhesion (adhesion), but passes through certain processing conditions (such as plasticization under high temperature conditions-injection molding, extrusion, laminating, gluing, etc.) , Making TPE and TPR close to the molecular polarity of another material, and under high temperature conditions, the two materials melt at high temperature, and at the same time, chemical molecules or molecular chains penetrate and entangle each other, causing adhesion. This adhesion is the cooperation and interaction of two materials, which is called the co-adhesion of TPE and TPR.

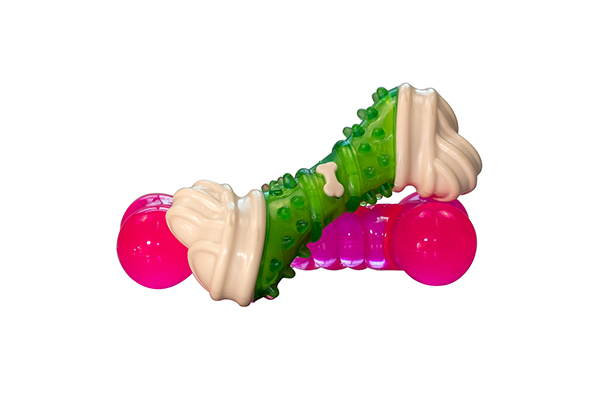

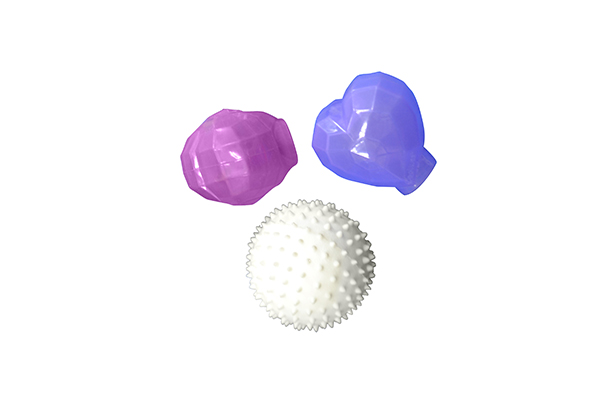

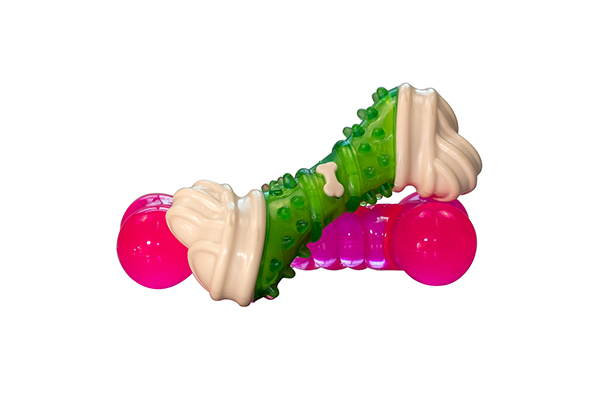

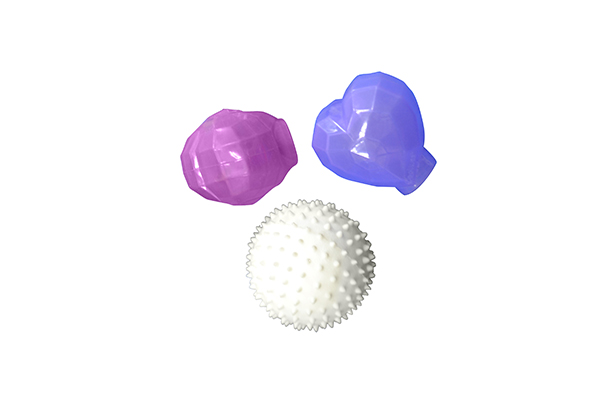

The common co-adhesion is the co-adhesion of TPE, TPR and plastic. It is a familiar name in the industry, namely overmolding, also known as overmolding, two-shot injection molding, two-color/multi-color injection molding, etc. The application of TPE and TPR encapsulation can be seen in daily life around the world. The co-bonding effect of TPE, TPR and plastic depends on the difference in polarity between the two materials and the surface tension of the plastic. At present, the industry can already provide mature technology TPE, TPR products, and most plastics, such as ABS, PA, PC, PP, PS, PCTG, PBT and other products with good mutual adhesion.

As the application of thermoplastic elastomers TPE and TPR continues to deepen and expand, the adhesive properties of TPE and TPR (including self-adhesive and co-adhesive) may gradually be applied to different industries, but user requirements may be different, which requires Continuous material research and development and innovation can provide TPE and TPR products that meet user requirements.