Different types of TPE encapsulation used to produce different products are also different. Today, let us understand the classification of TPE encapsulation.

1.TPE encapsulated ABS material

The basic formula of TPE encapsulated ABS material: SEBS SEBS TPU white oil additive filler, the specific formula is as follows, adjust the proportion of ingredients according to the actual cost and the desired effect. TPE itself has high hardness and poor flexibility, but TPU is a highly polar thermoplastic elastomer that has good adhesion to ABS polar engineering plastics. By adding TPU to the formulation, the polarity of the TPE encapsulation can be improved, thereby improving the adhesion between TPE and ABS. Due to the higher hardness of TPU, adding TPU to the blend will increase its hardness, and As the TPU content increases, the hardness of the material will continue to increase.

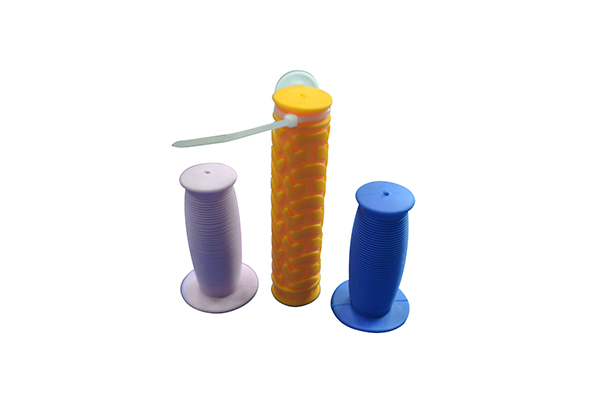

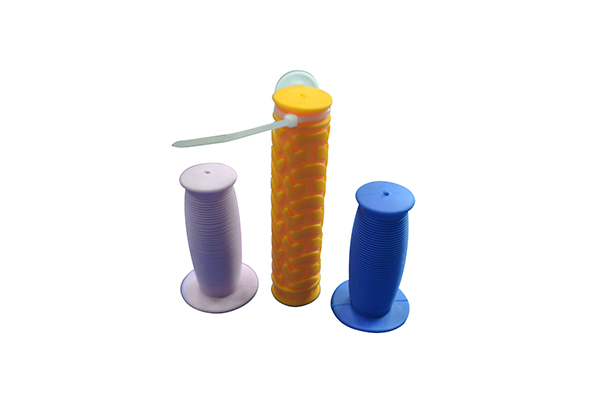

Application range: various tool handles, handles, game handles, electric toothbrushes, thermometers, audio knobs, electrical enclosures, instrument enclosures, electronic scanner enclosures, etc.

2. TPE encapsulated PP material

PP is a weakly polar plastic, very close to the TPE polarity of the SEBS substrate. All TPE soft rubber materials based on SEBS have a poor encapsulation effect, so it is not recommended to choose TPE encapsulation with SBS as the base material. TPE encapsulated PP material usually chooses about 20-90A hardness, and the color is divided into black, natural and transparent particles. TPE encapsulated PP can improve the comfortable feel and elasticity of the product, increase the slip resistance of the product, and enhance the grip of the product. The secondary injection temperature of TPE encapsulated PP material: The recommended secondary injection temperature is 180~220℃.

Applications: Daily necessities (such as combs, toothbrush handles, kitchenware handles, tableware handles, hardware tools), folding trash cans, sports equipment, folding washbasins, luggage handle products, kitchenware, folding bathtubs, tableware products, industrial casters , Folding cutting boards and other products that need to be packaged.

3. TPE coated PA material

TPE encapsulation has excellent physical properties and fluidity, has good adhesion/adhesive effect with PA nylon, is easy to injection process, and has wide adaptability. It is suitable for nylon PA6, PA66, PA12, PA6 GF, PA66 GF encapsulation Bonding.

Application areas: various household appliances, electric irons, power tools, hand tools, instrument housings, instrument housings, two-color handles and other product areas.

Four, TPE encapsulated PS material

TPE encapsulation and PS have good bonding effect and firmness. TPE encapsulation has rubber resilience, excellent adhesion to PS, good abrasion resistance and scratch resistance. TPE material has a comfortable and smooth hand feel, good material fluidity, and is easy to process and shape.

Application areas: tool handles, tableware handles, power tool handles, razor handles, rubber jumper handles, electronic digital product accessories, hardware tool products, sports fitness equipment accessories, sports equipment handles.

All in all, the above are some common types of TPE encapsulation. Of course, by adjusting the formula, the thermoplastic elastomer TPE can also be encapsulated with other hard plastics such as PE, PBT, POM, etc.